pv magazine test: December 2021 Results

By George Touloupas

This article was originally published in pv magazine – February 2022 edition. Learn more about the pv magazine test here.

pv magazine test involves a range of indoor tests, as well as an outdoor performance test in Gsolar’s test facility in Xi’an, China. Some of these tests are standard in the industry, while others are innovative and provide data on important module quality and performance issues.

Lab Report

Over the past two years, CEA and Gsola have been able to operate the pv magazine test facility without major disruptions. Unfortunately, Xi’an has been in the grip of a major Covid-19 outbreak for several weeks now, with strict lockdown and severe limitations to movement of people and the operation of businesses. As a result, the Gsola personnel have been unable to access the premises or collect the data for the outdoor test in time for the publication of the recent issue. Therefore, we instead present a detailed look at the indoor test report for the Longi Solar bifacial module, with product code LR5-72HBD-535M.

As part of CEA’s engagement in developing and supervising pv magazine’s test program at Gsola, CEA has developed a testing protocol and flowchart, a scoring system, a methodology and a reporting structure that is used to run the program, which we have presented in detail in previous articles. This report presents the test results and scoring grades for this product.

Test Details

Table 1: Test sample information

Table 2: Production information

A sample lot consists of five modules, one of which has been used as a spare for the chamber and outdoor testing, in case a module is accidentally damaged during handling at the lab. Refer to Table 1 and Table 2 for test sample and product information. Please note that the usual random selection procedure was not followed, the samples were selected and shipped to the lab directly by Longi.

Visual Assessments, EL Image Inspections and Other Tests

All five modules of the product sample lot have undergone visual and EL image inspection, according to CEA’s quality criteria. The defects found were evaluated according to CEA’s scoring system. Table 3 below shows the visual and EL image inspection results, normalized for the number of tested modules.

Table 3: Visual and EL Image Inspection Results

Table 4: Low-Irradiance Test Results

Table 4 above shows the test results for the Low irradiance efficiency loss, Pmax Temperature Coefficient, PID and LETID tests.

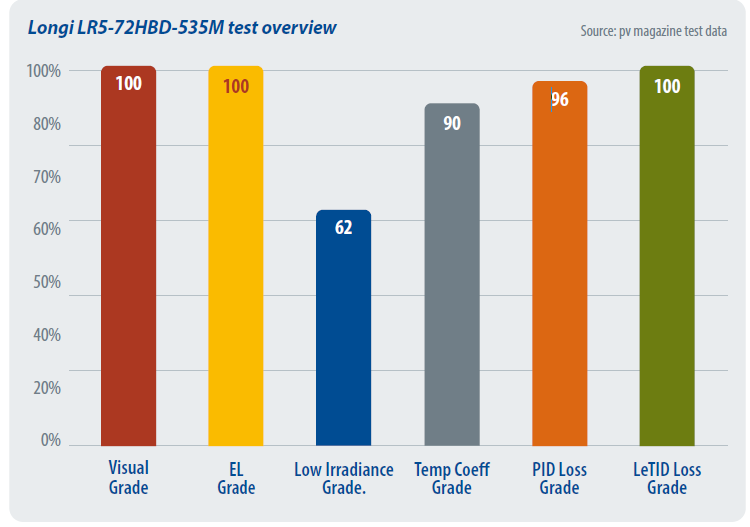

The low irradiance efficiency loss is calculated by the following formula: Efficiency loss = 1- [(Pmax at low irradiance conditions / Pmax at STC) * (1,000/200)]. The chart below (Figure 1) provides an overview of the scores.

Figure 1: Longi LR5-72HBD-535M Test Overview

Image 1: Five samples of Longi’s HiMo5 module (LR5-72HBD-535M) were sent to Gsola’s lab in Xi’an China. They are being put through their paces for pv magazine test.

Image 2: Rearside of the 144 cell glass-glass module

Image 3: Nameplate details of the module

George Touloupas is CEA’s Senior Director, Technology and Quality

Test Cooperation

pv magazine test is a cooperative effort involving pv magazine, APsystems, CEA, and Gsolar. All testing procedures are carried out at Gsolar’s test laboratory in Xi’an, China. CEA supervises these tests and designed both the indoor and outdoor testing procedures.